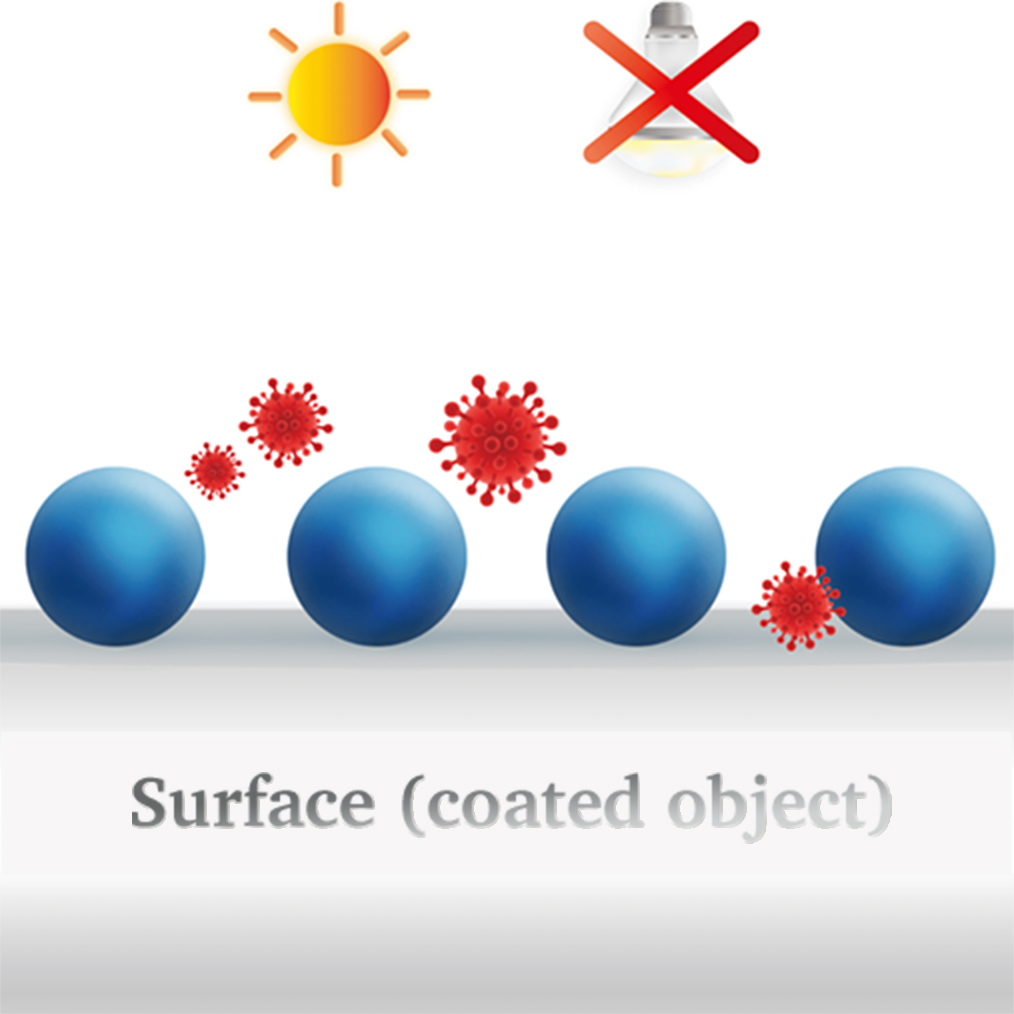

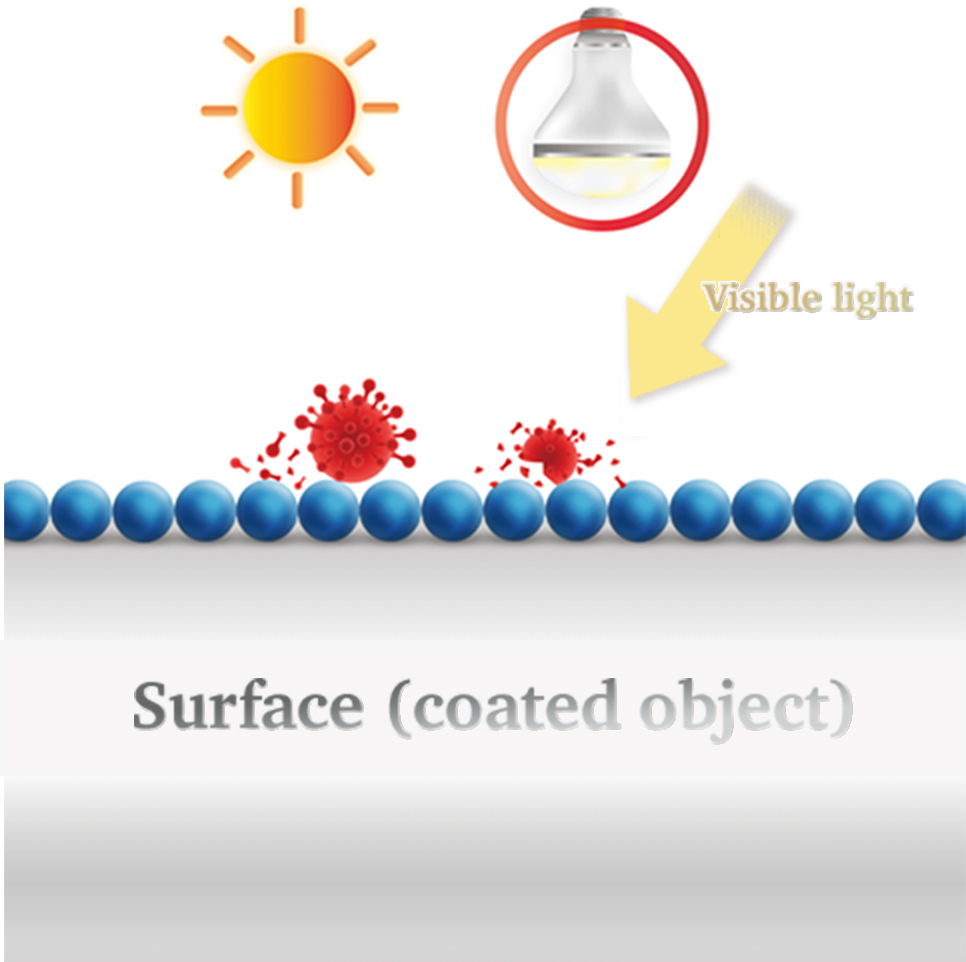

No longer need

disinfection work

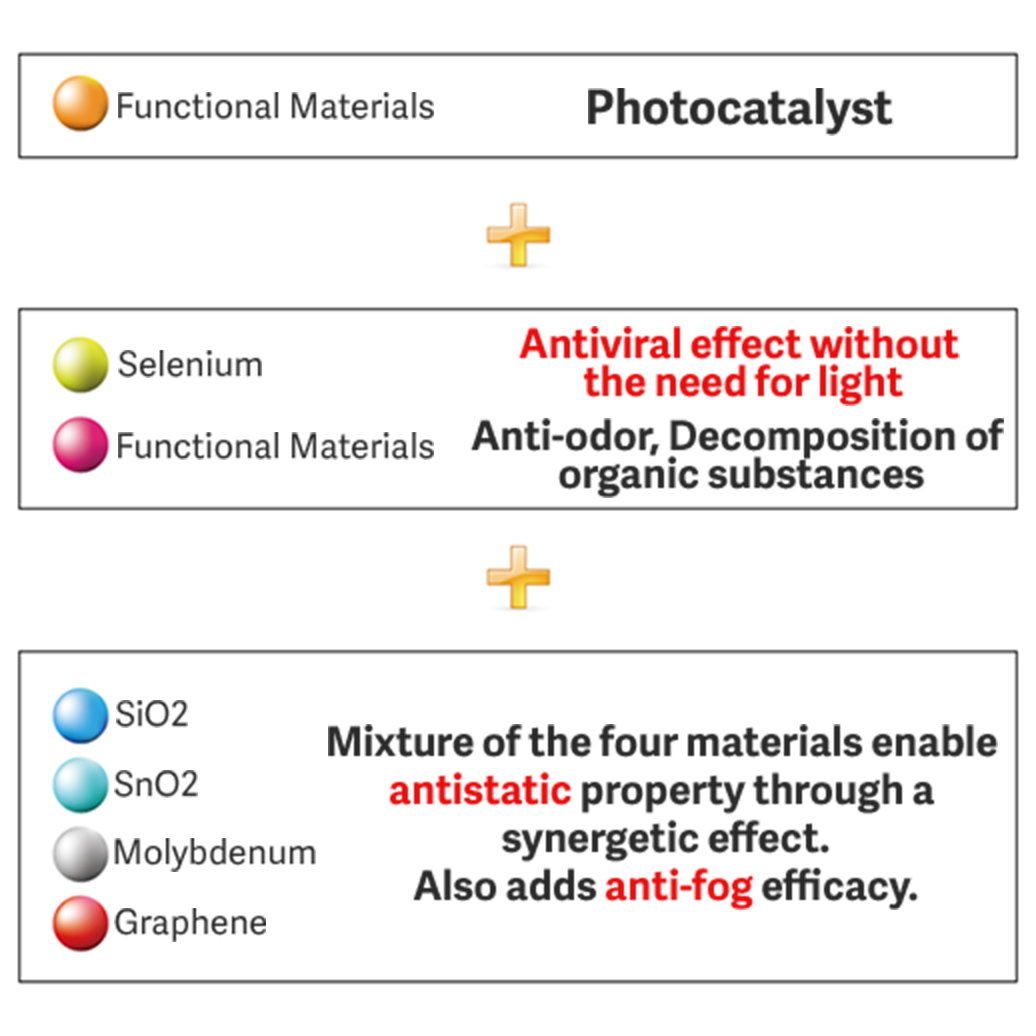

Mold Prevention

LANGUAGE

| Address | 12-16-3 Shiba, Minatoku, Tokyo, Japan |

| CEO | Eiji Watanabe |

| Inquiry | info@n-tec.store |